Product Category

Online consultation

Welcome to leave us a message, free to get product quotation.

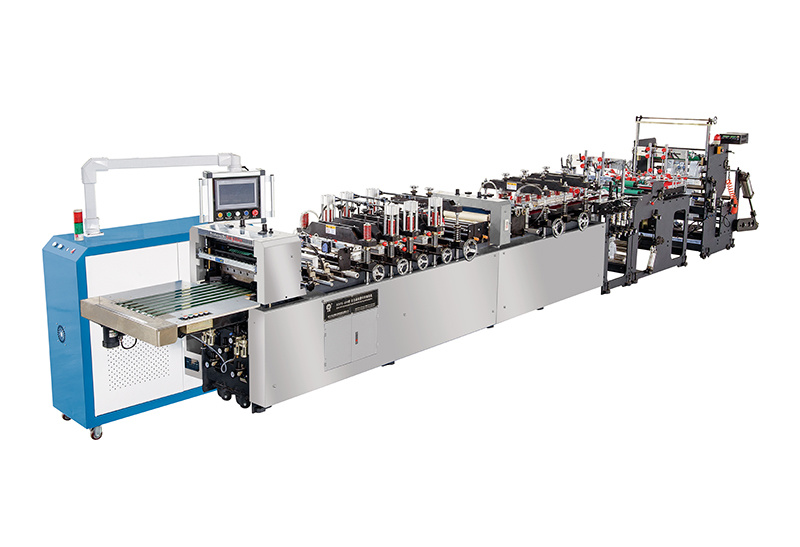

Using computer control for positioning three servo motors, the main motor features variable frequency speed regulation, dual photoelectric sensors for automatic material alignment, variable frequency automatic feeding for rear feeding, and automatic loading for rear feeding. Equipped with a movable fixed cutter, the cutter's front-back and tilt positions can be finely adjusted. It includes a multi-row double-edge bag slitting device and a material collection conveyor device. Ultrasonic zipper flattening, self-supporting high frame device, and automatic upper and lower zipper water plate devices are included. Features automatic batch counting, static elimination, edge material handling, pneumatic control for pressure rollers and tension. Functions include double feeding, high-level stop, tracking misalignment stop, material shortage alarm, etc. It offers high precision, fast speed, neat and elegant bag making, making it an ideal machine for producing plastic composite bags.

It adopts dual-servomotor location system controlled by computer, the main motor can regulate the speed by frequency conversion, the dual scanning heads can conduct automatic correction during material feeding and the rear delivery system feed the material by frequency conversion, it can automatic feeding the material. Equipped with removable fixed cutter, and you can minitrim the front, rear, slope position of the cutter. It can be used for sealing bags in either 1 row or 2 rows, enabling flexible configuration of different material layouts for production. It is equipped with material winding conveying device. It can automatically count the batch and amount, eliminate static and dispose the material edge. its pressed roller and its tensility both adopt pneumatic control. It has the function of multiple conveying, buzzing at startup, high-position stop, misplacement trailing stop and alarm for out of material. It features in high precision, fast speed, regular and beautiful bag making, so it is the ideal equipment for manufacture of laminated plastic bag.

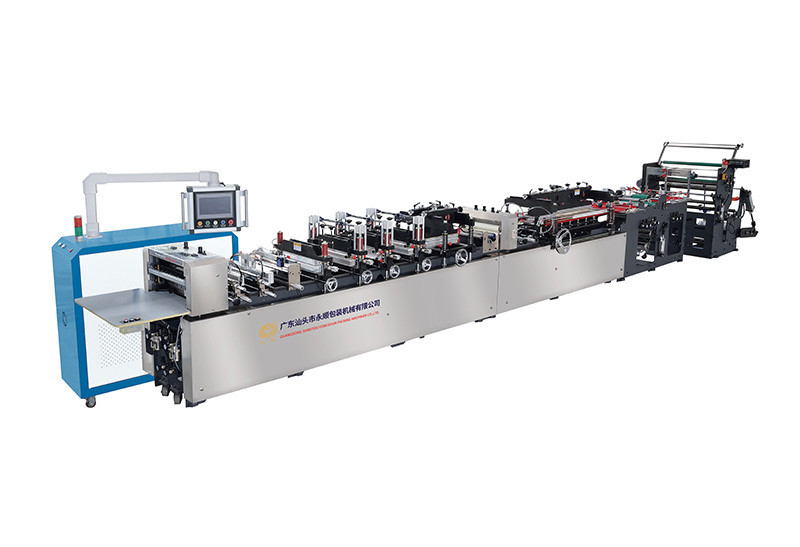

YFSDZ Fully Automatic Center Sealing Bag Making Machine with Double Row

The machine uses computer-controlled three-servo motor positioning, main motor frequency conversion speed regulation, feeding dual photoelectric automatic correction, and rear feeding frequency conversion automatic feeding. It is equipped with a movable fixed cutter, which can be finely adjusted in the front and rear and the angle. It is equipped with a material receiving conveyor. It has automatic batch counting, static elimination, edge material processing, and pneumatic control of pressure rollers and tension. It has high-position stop, tracking misalignment stop, and material-out alarm functions. It is characterized by high precision, high speed, flat and beautiful bag making, and is an ideal equipment for making plastic composite bags.

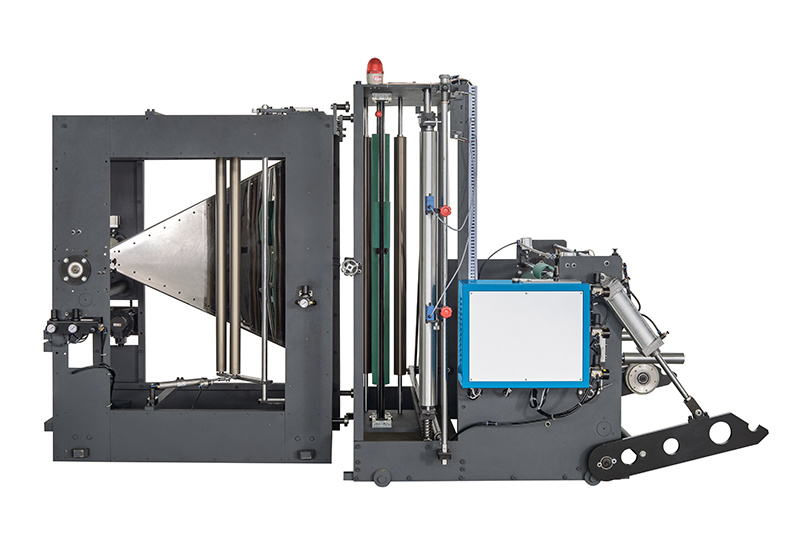

The equipment uses computer-controlled three-servo motor positioning, main motor frequency conversion speed regulation, feeding dual photoelectric automatic correction, rear feeding frequency conversion automatic feeding, unwinding rack plate-type horizontal folding device, and automatic rear feeding. It is equipped with a movable fixed cutting knife, which can finely adjust the front and rear and inclination of the cutting knife. It is equipped with a multi-row double-sided bag cutting device and a receiving conveying device. It has automatic batch counting, static elimination, edge material processing, and pneumatic control of pressure rollers and tension. It has functions such as multiple feeding, high-position stop, tracking misalignment stop, and material-out alarm stop. It features high precision, high speed, flat and beautiful bag making, and is an ideal equipment for making plastic composite bags.

The equipment uses computer-controlled dual servo motors for positioning, a variable frequency drive for the main motor, dual photoelectric sensors for automatic deviation correction in material feeding, and a variable frequency drive for automatic feeding of the rear material. It is equipped with a rotary cutter, allowing for fine adjustment of the cutter's front-to-back and angle positions. It also features a multi-row double-sided bag cutting device and a material receiving and conveying device. Functions include automatic batch counting, static elimination, edge material processing, and pneumatic control of pressure rollers and tension. It also has functions such as multiple feeding, high-position stop, tracking misalignment stop, and material depletion alarm. It is characterized by high precision, high speed, flat and neat bag production, making it ideal for manufacturing plastic composite bags.

YFS series fully automatic three-side sealing bagging machine

The machine uses computer-controlled three-servo motor positioning, main motor frequency conversion speed regulation, feeding dual photoelectric automatic correction, rear feeding frequency conversion automatic feeding, and a plate-type horizontal folding device for the unwinding frame, with automatic feeding for the rear feeding. It is equipped with a movable fixed cutting knife, which can be finely adjusted in the front and rear and the angle. It is equipped with a multi-row double-sided bag cutting device and a receiving conveyor. It has automatic batch counting, static elimination, edge material processing, and pneumatic control of pressure rollers and tension. It has functions such as multiple feeding, high-position stop, tracking misalignment stop, and material-out alarm. It features high precision, high speed, flat and neat bag making, and is an ideal equipment for making plastic composite bags.

The machine uses computer-controlled dual servo motors for positioning, a variable frequency drive for the main motor, dual photoelectric sensors for automatic material feeding correction, and a variable frequency drive for automatic rear feeding and material loading. It is equipped with a movable and fixed cutting knife that allows for micro-adjustment of the knife's front-to-back and angle positions. A material receiving conveyor is included. It features automatic batch counting, static elimination, edge material processing, and pneumatic control of the pressure roller and tension. Functions include multiple feeding, high-position stop, tracking misalignment stop, and material depletion alarm stop. It offers high precision, high speed, and produces flat, aesthetically pleasing bags, making it ideal for manufacturing plastic composite bags.

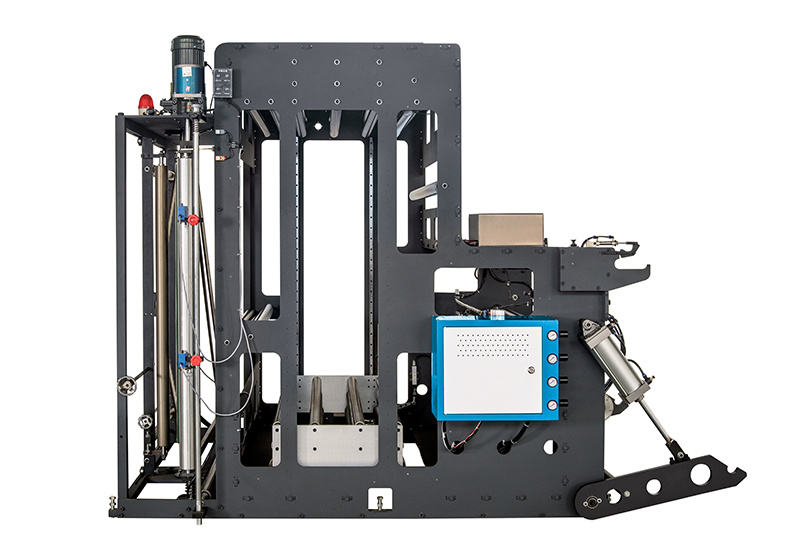

The machine uses computer-controlled three-servo motor positioning, main motor frequency conversion speed regulation, material feeding dual photoelectric automatic correction, and rear feeding frequency conversion automatic feeding. It is equipped with a movable fixed cutting knife, which can be finely adjusted in the front and rear and the angle. It is equipped with a multi-row double-sided bag cutting device and a material receiving conveying device. Ultrasonic zipper flattening, independent high-level device, and automatic up and down device for zipper water plate. It has automatic batch counting, static elimination, edge material processing, and pneumatic control of pressure rollers and tension. It has functions such as multiple feeding, high-position shutdown, tracking misalignment shutdown, and material-out alarm. It features high precision, high speed, flat and beautiful bag making, and is an ideal equipment for making plastic composite bags.

YFZZ fully automatic three-side seal, self-standing, zipper bag making machine

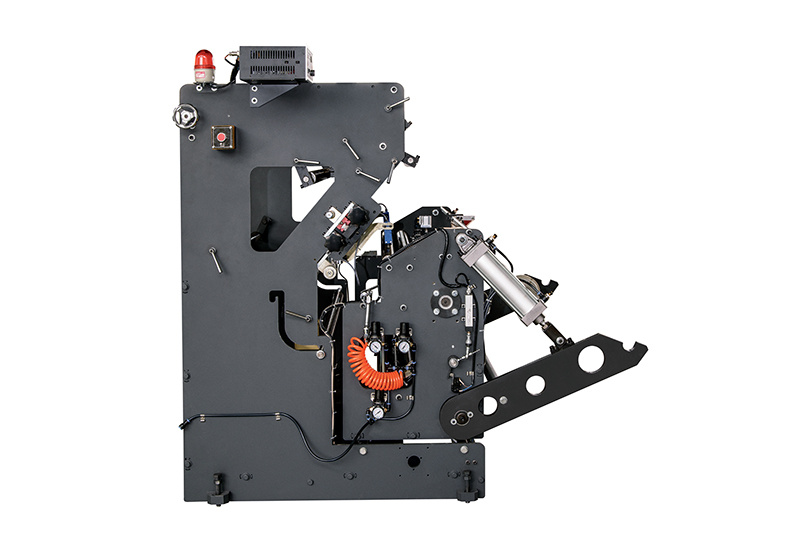

This machine is an auxiliary equipment for bag making machines, specializing in the production of three-side sealed and stand-up pouches. It uses a computer-controlled servo motor to drive the mold up and down, with five motors coordinating the movement. After receiving signals from the bag making machine, it automatically performs cutting, with pneumatic control for pressure rollers and tension. It features automatic batch counting, infrared sensor protection and shutdown functions. It is characterized by high precision, high speed, and long mold life, making it an ideal equipment for producing plastic composite pouches.

About Us

Products

Quick Navigation

Contact Us

Shantou yongshun packing machinery Co.,Ltd.

Address: No. 1, Mianhua School Qian Road, Ha Giang District, Shantou City, Guangdong Province

Postcode: 515073

Tel: 86-754-88224688

Fax: 86-754-88114699

Email: ysjx@ysjx.cn

Mobile Website

Service Number